Pancake Slip Rings

Pancake slip rings are designed for those have very limited height space but less limitation on diameter applications, also called platter separate slip rings or disc slip rings, they can utilize the existing bearings in the system to minimize the assembly height. In other words, a pancake slip ring can be without bearings.

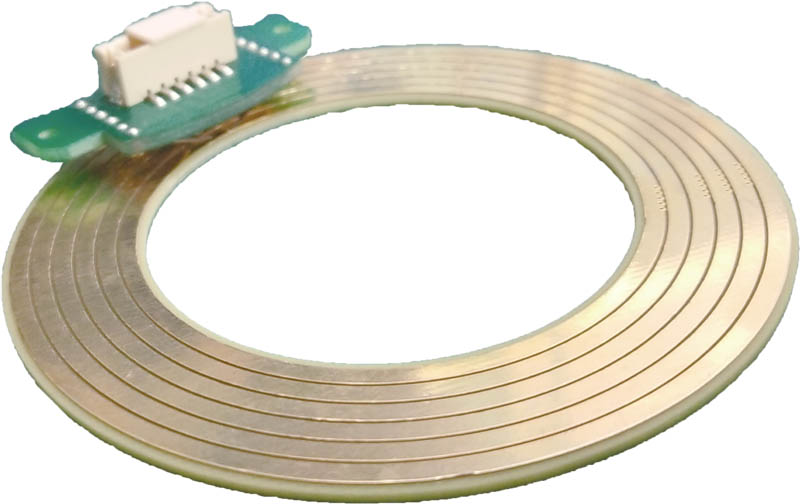

A pancake slip ring consist of a ring part and a matching brush block/board upon the requirement, and a specified through bore for shaft mounting. AOOD provides two types of pancake slip rings: PCB type slip rings and coin copper type slip rings.

Coin copper type pancake slip rings are vacuum molded from epoxy resin and have robust configuration, their sizes can be small or very large, are often used in CT scanner, radar pedestal and processing machinery. In some extremely limited height applications, both sides of the ring part can be vacuum molded to provide double power and signal rings for the system, moreover multiple platter slip rings can be used in the same system.

PCB type pancake slip rings are built on a PCB type ring and a matching brush block, they utilizing the existing bearing system to provide minimum installation height, have obvious price advantage on massive production.

They are ideal power & signal transmission solutions for requiring limited thickness mechanical systems, e.g. rotating tables and seat positions. AOOD provides two standard series PCB type units:

- For signal transmission PCB type pancake slip rings, each ring rated 2A ma, specially designed to transfer signal or lower current, provide smaller outer diameter and installation height.

- For power transmission PCB type pancake slip rings, each ring rated 10A max, can transfer both power and signal, rings can be designed on single side or double- sided of the PCB to provide a thinner thickness.