A slip ring is a rotary joint that used to provide electrical connection from a stationary to a rotating platform, it can improve mechanical performance, simplify system operation and eliminate damage-prone wires dangling from movable joints. Slip rings are widely used in mobile aerial camera systems, robotic arms, semi-conductors, rotating tables, ROVs, medical CT scanners, military radar antennas systems etc. There are five major factors affecting a slip ring’s operating lifetime:

1.The overall structure of the slip ring

Due to the customer’s actual system, mounting and budget requirements, we can provide them miniature capsule slip rings, through hole slip rings, disc slip rings, separate slip rings etc, but through hole slip rings and their derivatives have much longer operating lifetime due to structure advantages.

2.The materials of the slip ring

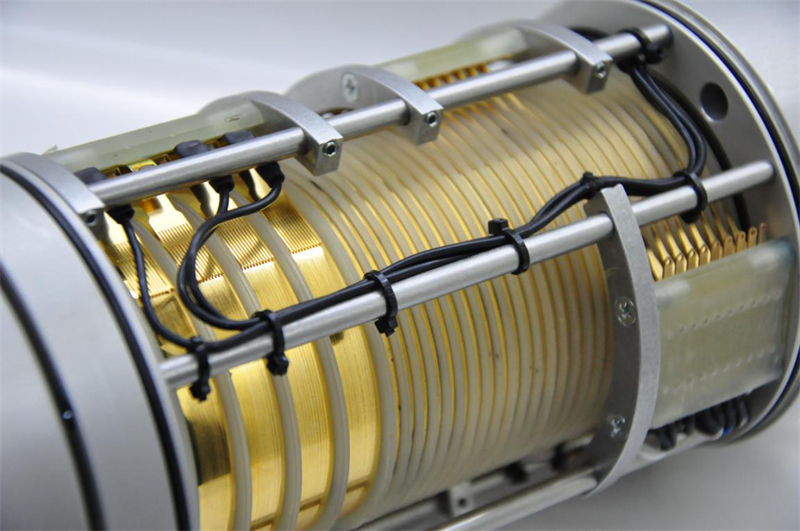

A slip ring’s electrical transmission is through the friction of the rotary ring and the stationary brushes, so the rings and brushes’ materials will directly affect the slip ring’s operating lifetime. Multiple alloy brushes is often used in production due to excellent wear-resistance capability. High quality insulation material is very critical too.

3.The slip ring’s processing and assembling

A slip ring’s long time smooth operating is the result of all components’ well coordination, so the slip ring manufacturer need make sure each component will be properly processed and assembled. For example, high quality gold plated rings and brushes will have smaller friction in rotation and extend its lifetime, skilled assembling will improve the slip ring’s concentricity, dielectric strength, insulation resistance, electrical noise and lifetime also.

4.The operating speed of the slip ring

A slip ring itself doesn’t rotate and has very small torque, it is driven to rotate by the mechanical device such as motor or shaft. Its operating speed need be smaller than its designed max speed, otherwise its lifetime will be shortened. Normally operating speed faster, the wear of brushes and rings faster and will affect its operating lifetime.

5.The operating environment of the slip ring

When the customer buys slip rings, the slip ring supplier should inquire the slip ring’s operating environment too. If the slip ring will be used outdoor, underwater, marine or other special environments, we need improve the slip ring’s protection accordingly or change materials to let it can suit the environment. Normally AOOD slip rings can operate 5 ~10 years with maintenance free under normal working environment, but if it is under high temperature, high pressure or corrosion special environments, its operating lifetime will be shortened.

Post time: Mar-18-2021