Pancake slip rings are designed for those have very limited height space but less limitation on diameter applications, also called platter slip rings, face type slip rings, flat slip rings or disk slip rings, they can utilize the existing bearings in the system to minimize the assembly height. In other words, a pancake slip ring can be without bearings to provide the shortest mounting height. A pancake slip ring assembly consists of a ring part and a matching brush block/board upon the requirement, and a specified through bore for shaft mounting.

With over 20 years designing and manufacturing slip rings experience, AOOD has grown into a leading slip ring manufacturer in commercial, industry and defense fields. AOOD pancake slip rings are more flexible with superior performance to meet the exact electrical, mechanical and operating conditions for each specific application, can be supplied from less than 25.4mm bore diameter disk type to over 2700mm bore diameter large CT scan slip rings.

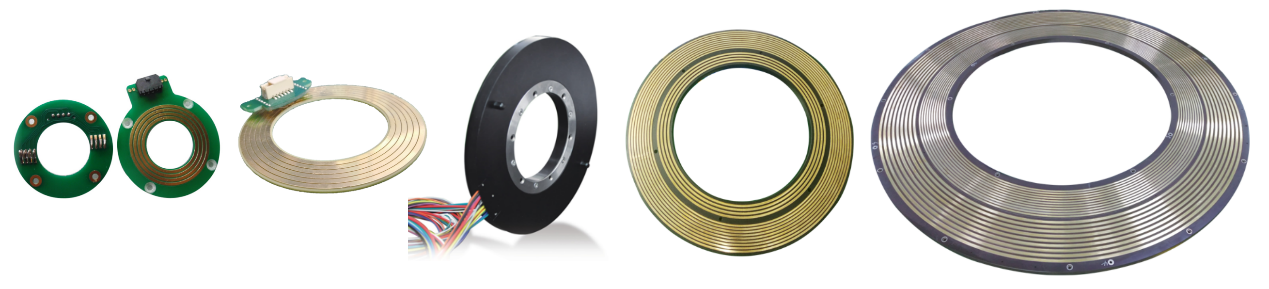

Disk Slip Rings

Disk slip rings are built on a PCB type ring and a matching brush block, they utilizing the existing bearing system to provide minimum installation height, have obvious price advantage on massive production. AOOD provides signal disk slip rings and power disk slip rings. Signal disk slip rings are designed with each ring rated 2A for signal or low current transmission, they can provide minimum 5.5mm mounting height, standard through bore diameters range 20mm to 100mm. Power disk slip rings allow max 10A per way for higher power transmission, provide minimum 9.2 or 15.2mm mounting height.

Enclosed Pancake Slip Rings

An enclosed pancake slip ring is a self-contained slip ring assembly, it consists of a ring part, a brush part, one or two bearings and a cover. Its performance is more superior than separate slip rings or disk slip rings, more robust structure can support higher operational speed and have sealing capability to meet the required IP rating. Enclosed pancake slip rings typically used in stabilized or mobile antenna pedestal applications integrating with coax/waveguide rotary joints to provide complete RF signal, electrical power and signals transmission solutions.

Defense Pancake Slip Rings

Defense purpose pancake / platter slip rings are not only more demanding in sizes than industrial pancake slip rings, but also more demanding in performance. These slip ring units may require to meet military shock and vibration requirements, wider operating temperature range, high speed operating, low electrical noise, low resistance, long lifespan and high reliability.

AOOD can provide sealed pancake / platter slip rings up to 13mm thickness for defense applications through cutting edge slip ring technology. AOOD even developed a high reliability 10 ways drum type self-contained pancake slip ring with only 15mm thickness based on 46mm centre hole and 90mm diameter.

Large Diameter Pancake Slip Rings

AOOD is also one of the few slip ring suppliers worldwide that can manufacture large size pancake slip rings. Large size pancake slip rings are well known as medical CT scan slip rings, often require up to 2700mm through bore diameter while operating up to 350rpm high speed with Gigabit Ethernet and large amount of data transfer, thus the design and production of large size pancake slip rings are very challenging. AOOD designs and produces large CT scan slip rings for over 10 years, proven performance and fast delivery enable us to be the first choice of CT scan slip rings suppliers of many customers. Large diameter pancake slip rings are also often used in luggage scanners, oil well pipe inspection machines, cranes, amusement rides, industrial 3D imaging equipment etc.

Post time: Jan-10-2022